The Characteristics and Advantages of CNC Boring

CNC Boring is used for the shaft sleeve in the transmission shaft of large equipment, and the tolerance of the bearing position is +0.03mm. After welding the accessories, use CNC horizontal boring and milling equipment to process both sides with a concentricity of 0.05mm.

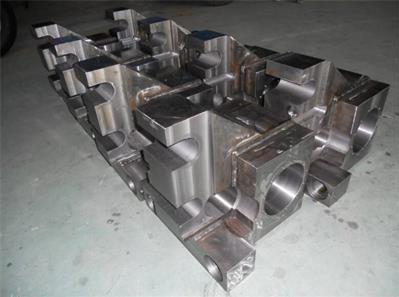

Product Description

CNC horizontal milling and boring machine is suitable for machining large and medium-sized parts and box parts rough and fine boring, milling and other processes. The worktable is equipped with 4×90 ° optical positioning device, which can meet the requirements of large parts turning. The CNC horizontal milling and boring machine is suitable for the hole and plane processing of box parts with many processes, turning of cylindrical surface, cutting of annular groove in hole, tapping of male and English screw thread with tap, etc. it also has the technological functions of rectangular coordinate system, polar coordinate system and contour processing of CNC machine tool. Because the CNC horizontal milling and boring machine has high rigidity and closed-loop detection system, which can meet the requirements of rough and fine machining, the CNC horizontal milling and boring machine is a high-efficiency and precision general-purpose large-scale machining equipment.

Table Display

| Machinery | 3 | |

| Material | Alloys Steel | Bronze Alloys |

| Aluminum Alloy | Stainless Steel | |

| Copper | Carbon Steel | |

| Brass | POM/PA | |

| Features | Deburring | Drilling |

| Tapping | Milling | |

| Threading | Boring | |

| Grinding | Knurling | |

| Maximum Dimensions | 6000mm*2000mm | |

| Milling Tolerance | ±0.01mm | |

| Inspection Capabilities | CMM | Projector |

| Imaging Measuring Instrument | Hardness | |

| Metallographic Microscope | Non-destructive Equipment | |

| Automatic Thread Inspection Equipment | ||

| Surface Finished | Zinc Plated | Sand Blasted |

| Nickel Plated | Blacking | |

| TD Coating | Phosphating | |

| Dacromet | Zinc-Nickel Plating | |

| Thread | UNF | UNC |

| NPT | SAE | |

| Metric | BSPP | |

| BSPT | JIS | |

| DIN | G | |

| R | ZG | |

| Certification | ISO9001-2008 | ISO/TS16949 |

Advantage points description

CNC boring and milling machining has the characteristics of strong rigidity, high machining accuracy and efficiency, good stability, long transverse travel, large bearing capacity and powerful cutting. It is especially suitable for the boring and milling of large plane and the finishing of large box parts and hole series. In addition to drilling, boring, expanding and reaming, various accessories can also be used for turning, milling and screw pattern processing.

FAQ

Alignment skills of CNC boring and milling machine

Generally, the mechanical origin of CNC boring and milling machine is set at the positive direction starting point of each axis when it leaves the factory, and the function of automatic coordinate system setting of each coordinate axis back to the reference point is not enabled. For the machine tool whose worktable can rotate, it is very inconvenient to find the programming origin of the four machining surfaces, so the production efficiency is low, After returning to the reference point, the automatic coordinate system is set, and the origin of the coordinate system is drifted. The origin of the new coordinate system is set as the intersection point between the spindle axis and the rotary axis of the worktable. The zero point of the A. Y axis can be set as the upper surface of the worktable or not, The parameter setting values of the origin of the new coordinate system are respectively the distance between the mechanical origin of each axis and the origin of the new coordinate system. The value is input into the setting parameters of the automatic coordinate system, and it can be effective by returning to zero again. Thus, when the programming origin coordinates of four machining surfaces of a part are aligned, the programming origin coordinates of other machining surfaces can be converted

What should be paid attention to in application of CNC milling and boring machine

Horizontal milling and boring machine should be installed in a place far away from the seismic source, not directly exposed to sunlight, no heat radiation and no humidity. If there is a seismic source around the place where the equipment is installed, an earthquake proof trench should be set up around the equipment. If there is no shockproof groove, the machining precision and stability of the equipment will be directly affected. If the time is long, the bad contact of electronic components will be affected, and the reliability of horizontal milling and boring machine will be affected.

Causes of inverted taper hole in CNC boring and milling machine

In the process of machining, the fit clearance between the outer circle of the boring shaft and the inner hole of the hollow shaft is too large, which leads to the increase of the linear error of the boring shaft; after the matching grinding, the fit clearance between the outer circle of the hollow shaft and the bearing is too large, which leads to the increase of the axial cumulative error of the drilling in the vertical and horizontal directions.

Correct operation procedure of CNC boring machine

CNC boring machine is a kind of machine tool which mainly uses boring cutter to bore the pre-existing holes. Generally, boring tool rotation is the main motion, and the movement of boring tool or workpiece is feed motion. It is mainly used for machining high-precision holes or finishing multiple holes at one time. In addition, it can also be used for machining other machining surfaces related to hole finishing. Different tools and accessories can also be used for drilling and milling. The machining accuracy and surface quality of cutting are higher than those of drilling machine. CNC boring machine is the main equipment for machining large box parts

Routine maintenance of CNC boring machine

CNC boring machine is the main equipment for machining large box parts. In the daily maintenance of CNC boring machine, the main thing is to pay attention to cleaning, lubrication and reasonable operation.

Media Contact

Company Name: Shanghai ETCN Electromechanical Equipment Co., Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: +86 13917077495

Address:Room 2310, No.39 South Chezhan Road

City: Shanghai 200434

Country: China

Website: https://www.machining-in-china.com/